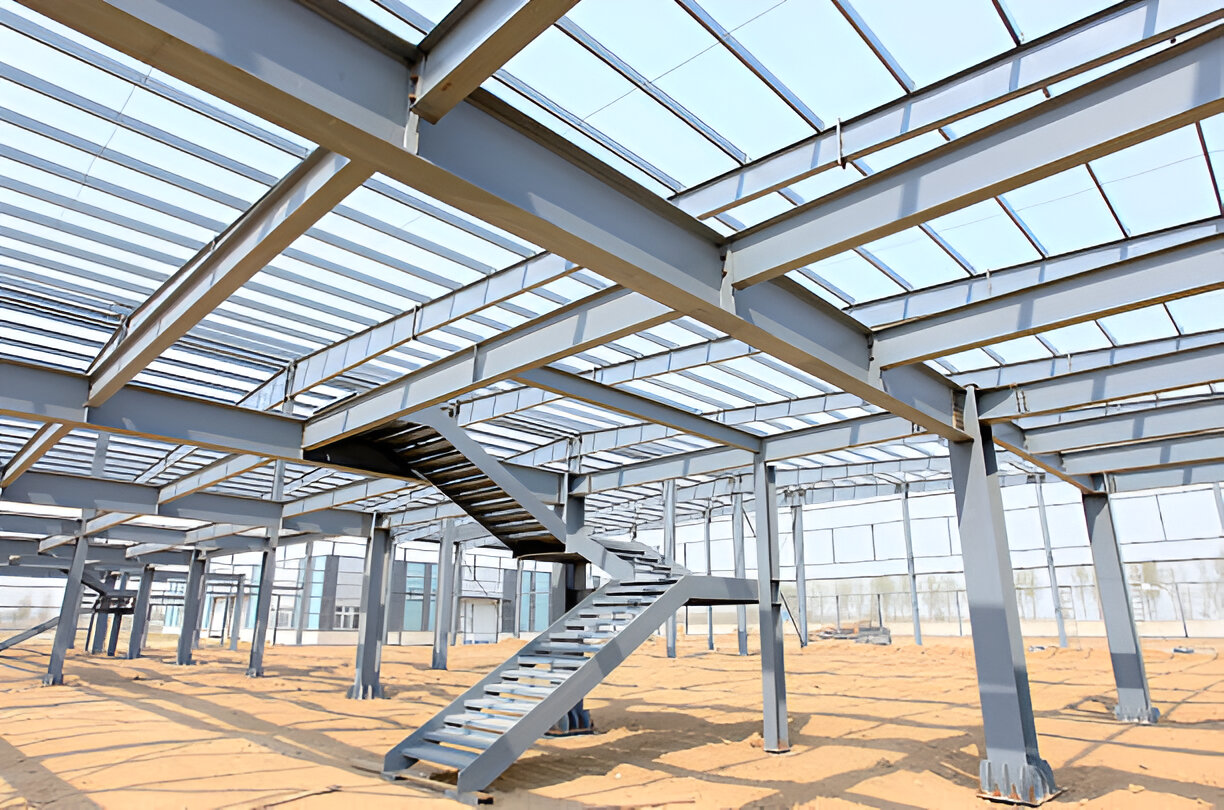

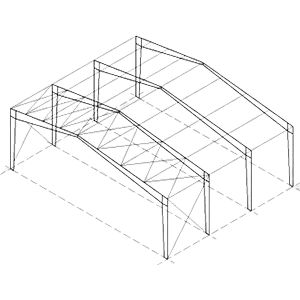

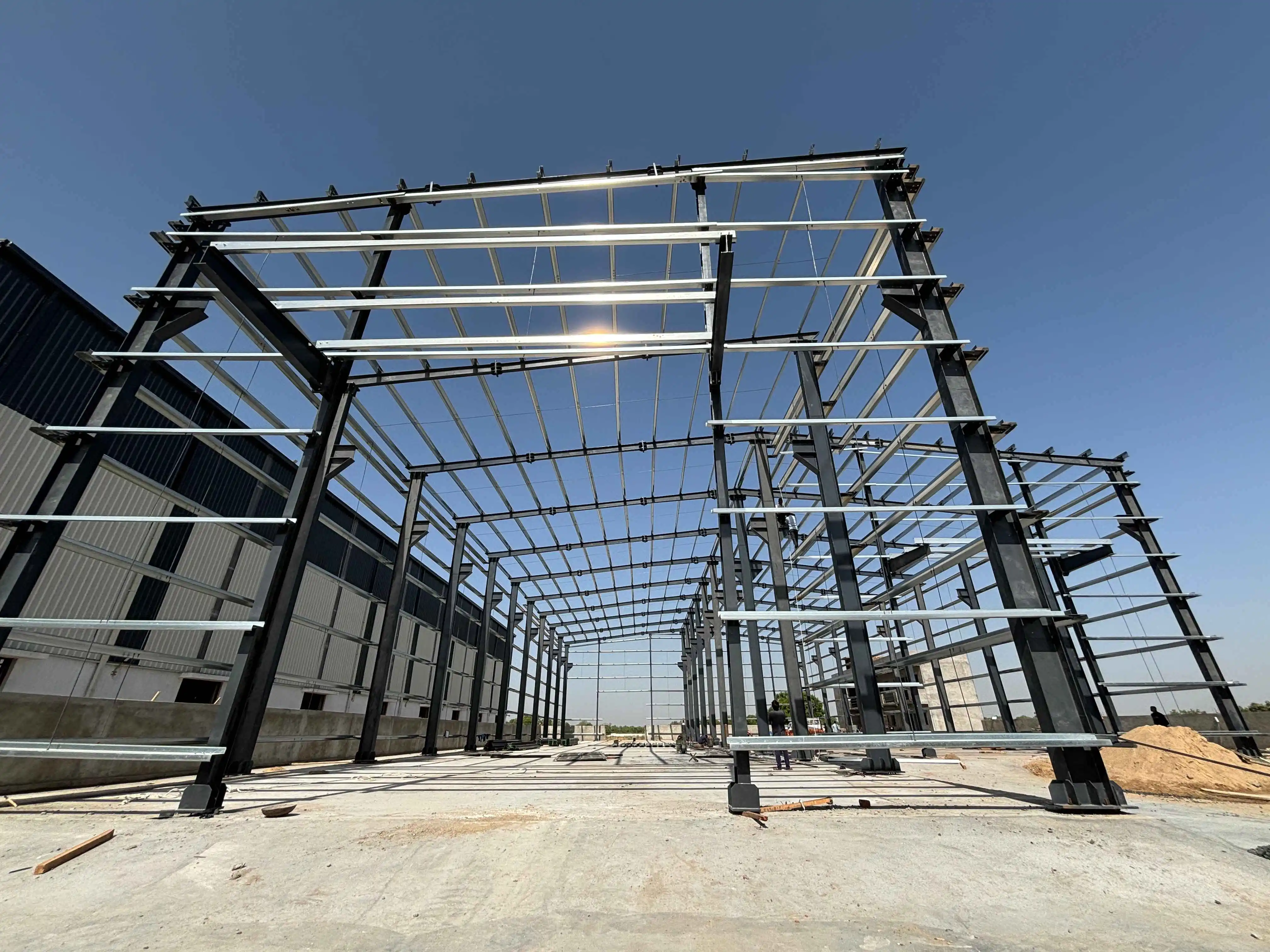

Main framing usually refers to the basic rigid steel frame of any particular building. The rigid frame that we provide consists of tapered columns and rafters. Usually, there are high-quality flanges that connect to the web with a continuous filet weld. We strongly believe that any of the buildings drive strength from none other than the Main Framings. Hence, the base has to be strong to add value and cohesiveness to the entire building.